With the sport of baseball as an important symbol of American culture, custom baseball patches have become a popular choice for teams, fans and collectors. Whether it is the classic texture of embroidery or the flexible design of heat transfer printing, the choice of different processes directly affects the durability, cost and application scenarios of patches. This article analyzes how to customize patches from four dimensions: embroidery process comparison, scenario-based demand matching, budget optimization strategy and supplier selection criteria. four dimensions, to analyze how to customize the baseball patches that best fit your needs.

Hand-embroidered vs heat transfer: process characteristics and applicable scenes

Hand-embroidered patches are made with high-density stitching, which is highly durable and especially suitable for team uniforms that are washed frequently or souvenirs that are kept for a long time. For example, professional baseball teams often use multi-layer embroidery with a 3D effect to highlight the three-dimensionality of the team logo, and the colors remain vibrant even after hundreds of machine washings. Heat transfer patches, on the other hand, can be applied by high-temperature lamination and cost as little as $0.40, making them ideal for short-term events (e.g., charity game T-shirts) or personalized items (e.g., fan support hats). However, it should be noted that heat transfer patches may crack at the edges after repeated rubbing, so they are not recommended for high-frequency contact scenes such as baseball gloves.

Second, from the demand: team, tournament and personal customized design logic

- Team logo:

The embroidery process is used to strengthen the sense of collective honor, such as combining the team’s founding year, slogan and mascot, and adding reflective stitching to enhance nighttime recognition.

Referring to the patch design of the MLB team “San Francisco Giants”, the Golden Gate Bridge is embroidered, and the edges are outlined with metallic threads to emphasize the regional characteristics. - Tournament commemorations:

Mixed use of embroidery and heat transfer: embroidery for limited edition souvenirs (e.g. championship ring box) and heat transfer for participant giveaways (e.g. 5,000 race T-shirts). - Personal Collections:

Vintage style patches (e.g., do-over stitching) and hidden details (e.g., family crest initials) are more popular, and can refer to the gradient color technique of Suzhou embroidery to enhance the artistic value.

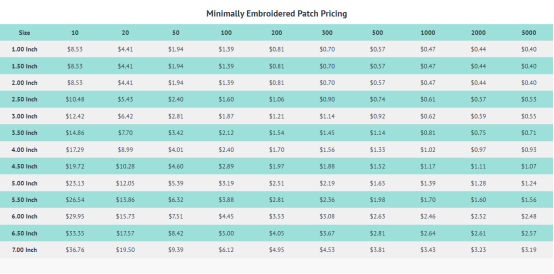

Cost Control: The Golden Balance between Order Quantity and Process Selection

Fourth, the supplier screening: 5 indicators to avoid the trap of poor quality

- material certification: OEKO-TEX Standard 100 non-toxic dyes required to provide proof, especially when it comes to children’s team orders.

- sample testing: after receiving the digital design, you need to conduct a “violent test” (machine wash 10 times + drying), to observe whether the stitching is off or pattern displacement.

- Copyright compliance: If official logos such as MLB, NCAA, etc. are used, confirm that the supplier has authorization documents (e.g. MLB Properties certification).

- Delivery cycle: Priority is given to vendors who promise “10-14 days delivery” and clear compensation terms for delays (e.g., 2% of the daily order amount).

- Environmental process: Recommended use of recycled polyester fiber (rPET) base cloth, in line with the California AB 1817 bill on sustainable textiles requirements.